Infineon has launched its XENSIV SP49 tire stress monitoring sensor, which integrates MEMS (micro-electromechanical techniques) sensors and ASIC to offer superior tire stress monitoring techniques. It encompasses a 32-bit Arm M0+ core, flash reminiscence and RAM, Low Energy Monitoring (LPM), and optimized quick acceleration sensing. The SP49 is supposed for clever tire capabilities comparable to on-tire auto-position sensing, tire inflation help, tire blowout detection, and cargo detection.

Handily for carmakers, the SP49 is a pin-to-pin substitute for its predecessor, Infineon’s last-generation SP40 TPMS merchandise. Because of its built-in microcontroller, sensors, and handy peripherals, the SP49 requires just a few passive elements to kind a whole TPMS sensor unit. The system is designed for low energy consumption, making it supreme for battery-powered functions.

Design Information was interested in this software of MEMS know-how to a TPMS, so we requested to talk with Kim Lee, the corporate’s Senior Director of Methods Functions Engineering for Sensors, Options, and IoT for the Americas.

MEMS looks as if an surprising know-how for a TPS. How does it work?

Kim Lee: MEMS has largely been used for TPMS in recent times. Piezoresistive applied sciences for TPMS use a MEMS course of the place the straightforward circuit mannequin is 4 resistors positioned on a silicon diaphragm that measures the results of pressure or bodily stress utilized upon them. This stress causes a change in resistance that’s being transformed via a bridge circuit into an output voltage.

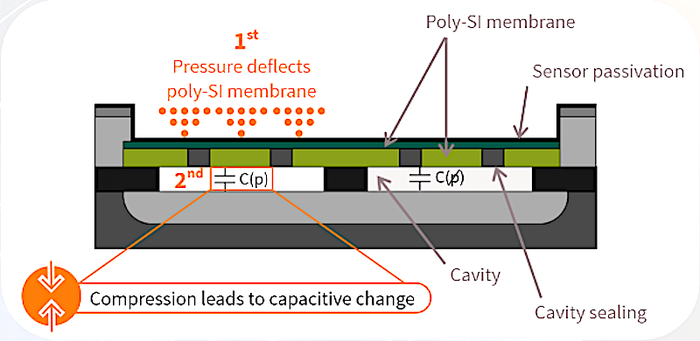

Infineon’s TPMS makes use of a capacitive approach which is best for accuracy and low energy. The capacitive MEMS makes use of two parallel and electrically remoted conducting plates the place the underside plate is fastened whereas the highest one is delicate to stress modifications. When stress is utilized, the highest plate (or membrane) bends and a capacitance change is created.

This variation in capacitance is then translated to {an electrical} sign the place it may be learn and conditioned by a microprocessor or ASIC. Most newer TPMS merchandise comparable to Infineon’s SP40+ household incorporate the processing ASIC and extra right into a single IC package deal. This illustration beneath can present a visible illustration of the MEMS construction.

MEMS TPMS. INFINEON

What are the advantages of utilizing MEMS?

Lee: MEMS know-how has been predominantly used for direct stress sensing in TPMS functions. Oblique methods use wheel pace via the braking system to sense tire stress. However even accelerometers and gyros are utilizing MEMS know-how.

The present TPMS know-how makes use of MEMS capacitive stress sensors that provide glorious long-term stability and higher accuracy. These MEMS capacitive stress sensors even have low energy consumption since there isn’t a DC present flowing via the sensor component attributable to its nature and due to this fact eat very low energy in sensing stress.

Can this method predict issues slightly than simply react to them?

Lee: The TPMS screens the stress sensor and feeds the knowledge to the central processing unit to show the tire stress on the driving force’s instrument panel. Some automobiles simply have an LED mild indicating low tire stress.

It is a sort of prediction for low tire stress warning and alerting the driving force to deal with it by checking the tire or including extra air. Extra subtle algorithms can be utilized to find out the speed of stress change and decide if the air stress delta is a gradual change (gradual leak) which can be okay to drive one other 50 miles earlier than addressing, or a quick sufficient change the place any additional driving will trigger a possible accident. The algorithm would reside within the processing unit that takes the TPMS knowledge, determines predictive behaviors, and suggests particular actions.

How can the load detection be employed by truck producers to offer drivers essential data?

Lee: Load detection via TPMS might be attainable by monitoring the tire stress throughout an unloaded truck, after which computing the delta on the tire stress when the truck is loaded with cargo. The load of the truck may be correlated to the air tire stress to offer driver data. A separate MEMS stress sensor may be utilized to the system that detects the load of the truck itself outdoors the TPMS system as a separate manner of measuring load weight.

What are the potential future capabilities of this know-how?

Lee: MEMS know-how is utilized in many functions comparable to microphones, gyrometers, accelerometers, ultrasonic sensors (identical as a microphone besides utilizing the >40kHz band), magnetic sensors, and gasoline sensors. Infineon incorporates MEMS know-how in lots of our sensor merchandise that you simply see on our web site together with our TPMS sensors.