Prefer it or hate it, because the motherboard trade has advanced, the emphasis on design and aesthetics has grow to be a larger issue. Partially, this can be a facet impact of the PC turning into extra of a luxurious merchandise; there’s a myriad of useful options–tablets, laptops, telephones, and consoles–that we will use for gaming and primary computing duties. These gadgets are aesthetically pleasing and ergonomic, and most of them are designed to enrich your residing area. In distinction, PCs are sometimes a lot bigger, they are often difficult to construct for first-time DIYers, and till lately, color-matching elements has been troublesome.

That’s why ASUS is striving to make it simpler for customers to customise the beauty look of their PC elements. For instance, ASUS motherboards with Aura lighting have RGB LEDs that permit customers to tweak colours and results to match different system {hardware}. We’re now producing motherboards like the Rampage V Version 10, which has a impartial, monochromatic colour scheme that appears nice as-is and even higher with the accent lighting that Aura offers. We’ve additionally created the ROG Licensed program to work with distributors creating PC elements which have a visible and useful synergy with ROG merchandise.

The Rampage V Version 10

The Rampage V Version 10

For probably the most half, the shift in direction of monochromatic themes and RGB lighting has been met with reward, extra so by these of us who have been constructing PCs for quite a lot of years, as we will recall the place issues weren’t that way back.

The 3D-printable future

The pliability {that a} impartial colour scheme and RGB lighting offers is welcome as a result of it provides customers extra management over how a system appears to be like, however colour is only one facet of aesthetics. A element’s bodily kind is simply as essential. Due to this fact, offering customers with choices to change the form of their {hardware} needs to be the subsequent milestone. That’s the place developments in 3D printing know-how will help.

The benefit of 3D printing is that one-off designs and small-scale manufacturing don’t require the extortionate tooling charges related to typical manufacturing strategies, opening up a number of potentialities for DIY lovers. A stage of competency with CAD software program is required to develop issues your self, after all, however we will help by designing merchandise to just accept printed components and by offering 3D supply recordsdata that customers can modify. With that in thoughts, we unveiled some conceptual 3D-printed components for ASUS motherboards at Computex a number of months in the past.

An array of 3D-printed motherboard elaborations at Computex 2016

Lots of the gadgets featured on the ASUS sales space have been aesthetic enhancements primarily centered on overlaying cables and different elements. These items have been impressed by the success of the motherboard IO shroud proven beneath.

The X99-Deluxe–the primary outing for the now notorious motherboard IO shroud.

First launched by ASUS as a part of the predominantly black-and-white colour scheme for the X99-Deluxe, the IO shroud was an on the spot hit. The gross sales figures for the X99-Deluxe mirrored that, however I can’t share these numbers with you. Nonetheless, I’ll share this: whereas we will’t pin all the board’s success on the shroud, this was the primary time in current historical past that the Deluxe outsold all different ASUS high-end desktop motherboards. For us, this confirms that getting the aesthetics proper issues loads.

Earlier than we get forward of ourselves, we must always take a while to debate the restrictions of 3D printing. Our preliminary makes an attempt at creating components confirmed that gradients look somewhat tough, particularly when items are bigger than a number of centimeters. That is because of the manner most 3D printers work. Every bit is constructed up in layers, and on any gradient, these layers will present within the closing product as a step-like sample. This occurs even should you ask a 3D printing provider to shine a chunk for you. Items could be completed by hand, however bringing bigger ones as much as acceptable requirements can require lots of elbow grease. That most likely gained’t deter hardcore modders, though I think it is going to discourage informal DIYers. Ideally, gradients should be used sparingly.

For these of us with out 3D printers of our personal, massive gadgets could be costly to print, which outweighs the enchantment. Meaning the main focus needs to be on creating smaller gadgets and accounting for the restrictions of 3D printing on the design stage. We additionally really feel there’s a necessity to take care of aesthetic steadiness; massive gadgets could be overbearing, as a result of they take the main focus off the {hardware}. Go too far, and a motherboard can find yourself wanting like an overdressed boy-racer vehicle somewhat than a refined piece of electronics. That’s one thing we’re eager to keep away from.

We shouldn’t permit ourselves to be deterred by the limitations, as a result of there are many alternatives to supply smaller components, together with ones with extra than simply aesthetic benefit. In that regard, there was one merchandise on show at Computex that caught our consideration:

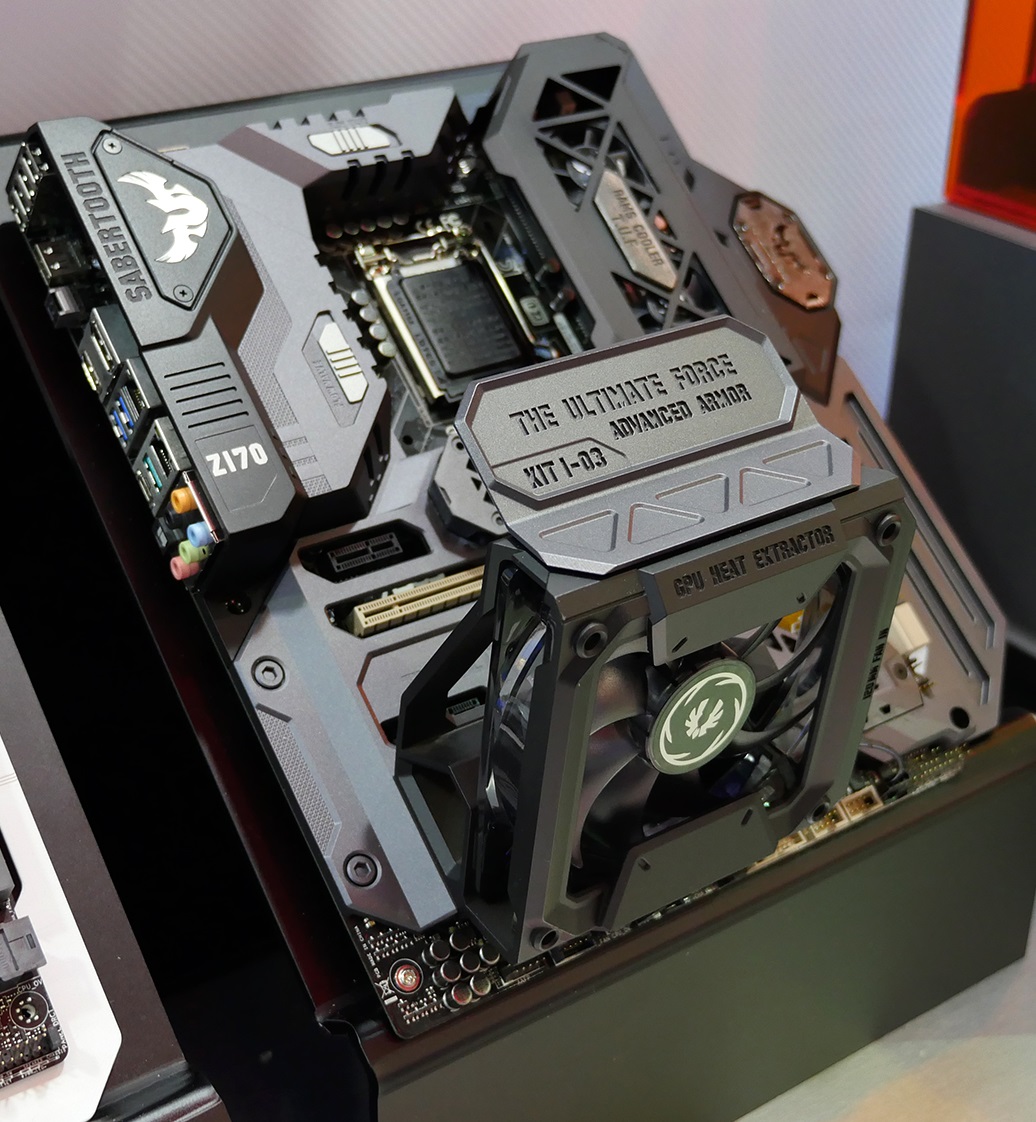

A mixed 120-mm fan mount and graphics help for the Sabertooth Z170

Designed for the Sabertooth Z170 Mark 1 motherboard, the mixed 120-mm fan mount and graphics card help is an fascinating thought. Graphics playing cards have grow to be heavier through the years, which causes them to sag when put in in a PCI Categorical slot with out extra help. The airflow in some PC chassis can also be poor, which may result in elevated GPU temperatures. In concept, an merchandise like this tackles two irksome points. That is the kind of factor that stirs our creativeness concerning what can and needs to be carried out with 3D printing.

We displayed 3D-printed components at Computex to solicit suggestions from attendees. Across the identical time, we have been additionally finalizing an enhanced model of our Z170 Professional Gaming motherboard. This replace was prompted by suggestions from system integrators, who requested including a splash of RGB lighting, altering to a extra impartial colour scheme, and reinforcing the PCIe slots.

Priced at $165, the Z170 Professional Gaming/Aura

Because the timeframes for Computex and finalizing this motherboard coincided, strategies from modders and system integrators additionally prompted our R&D staff to make the Z170 Professional Gaming/Aura somewhat extra pleasant to 3D printing. The suggestions steered including devoted mounting factors for 3D-printable components reminiscent of nameplates. Though it was too late to remodel the motherboard’s hint structure to accommodate a lot of mounting factors, we managed to squeeze a pair into the decrease left nook of the PCB:

The Z170 Professional Gaming/Aura’s mounting factors for 3D printed components

These 3D Mounts use the identical screws as M.2 drives to anchor 3D-printed components to the motherboard.

A 3D-printed cable cowl with a customizable brand for the Z170 Professional Gaming/Aura

The preliminary plans have been to make the most of the devoted mounting factors to create a canopy for the audio circuitry. Nonetheless, suggestions from modders and system integrators led to the creation of the cable cowl and brand panel proven above. Whereas the situation is considerably obscure, I can perceive the intent; with the ability to combine a customized brand is a gorgeous function for system integrators. And whereas I’m all for displaying off sleeved cables, sleeving smaller front-panel wiring could be time-consuming, so the choice to cowl it up is interesting.

As we stated earlier, we like the thought of using 3D printing to resolve irksome points. Most motherboards have no less than one M.2 slot, and it’s normally positioned close to the PCIe slots. Whereas this location is smart aesthetically and electrically, it’s not the perfect for airflow. M.2 SSDs can get sizzling when pressed for information over sustained durations, and people elevated temperatures can set off throttling that reduces efficiency. Thermals may also have an effect on NAND retention and endurance, so most customers are keen to maintain their drives as cool as attainable. As proven on this M.2 SSD throttling article, offering some airflow over a drive helps to decrease temperatures.

So, when ASUS HQ prompted us for suggestions on 3D-printed components for the Z170 Professional Gaming/Aura, we steered a fan mount for M.2 drives.

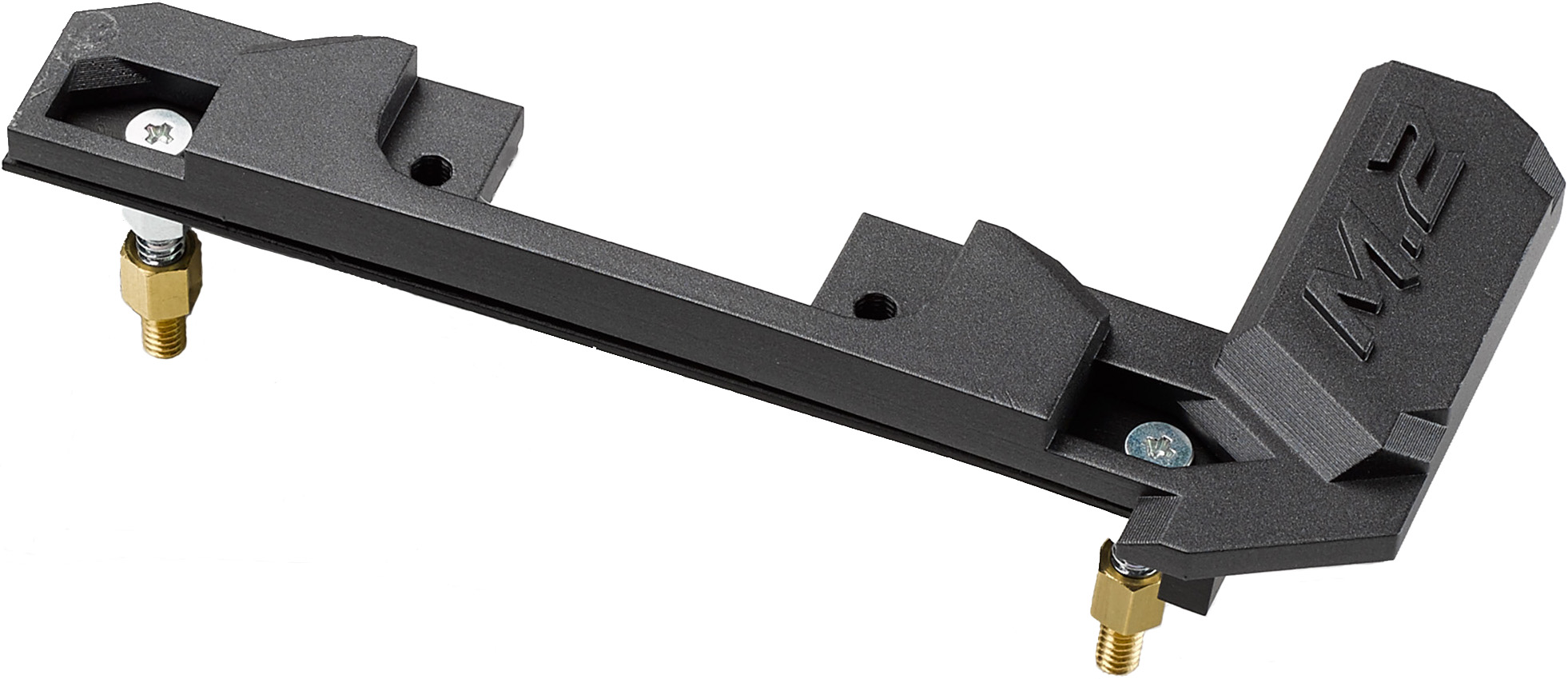

A 3D-printable 40-mm fan mount for cooling M.2 drives

The M.2 fan mount and fan, in situ

The design above makes use of the usual motherboard mounting holes as an alternative of the board’s devoted 3D Mounts. Set up requires a pair of stand-offs no less than 6.5 mm tall. We opted for this strategy as a result of the slot is near the usual mounting holes and the M.2 cooler is straightforward to put in as soon as the motherboard is contained in the chassis. The one factor that makes this design particular to the Z170 Professional Gaming/Aura is the situation of the M.2 slot on the motherboard.

Relying upon the fabric you select, the price of printing a smaller gadgets like this is clearly extra agreeable than for bigger items. The M.2 cooler needs to be straightforward for anybody with a 3D printer to make themselves, or you may have it printed by an internet service like Shapeways for lower than $12.

Extra 3D-printable enhancements

The cable cowl additionally sparked a number of concepts for a number of off-board nick-nacks which might be rising in popularity: cable combs and SLI bridge covers. The marketplace for sleeved cables has exploded over the previous few years; there are distributors devoted to producing cables to order, full with totally different colours for particular person wires. When these cables are put to make use of, builders desire to maintain them tidy and arranged, which in flip creates a necessity for cable combs.

In reality, there’s no scarcity of cable combs available on the market. However the prospect of a design that you could personalize or adapt for a given theme is cool.

A 3D-printed, 24-pin cable comb

This isn’t the kind of comb you’d use for each energy connector in a system, however there’s scope to change the design to make it much less directional and even add a personalised brand.

There’s the same demand for aftermarket SLI bridges, as a result of those that come bundled with motherboards don’t look good and are sometimes the sore thumb in any showcase PC construct. Like with cable combs, aftermarket bridges can be found, however the colour and design choices are restricted–cue one other 3D-printable merchandise ripe for experimentation:

An SLI bridge cowl you may print your self

The bridge cowl is designed to clip onto the PCB SLI bridges which might be bundled with some motherboards. I’ll admit, it isn’t freed from visible defects, however a little bit of sanding ought to assist buff issues as much as a suitable stage. It’s additionally attainable to color gadgets like this to get simply the proper colour.

There’s room for 3D-printed components on peripherals, too. Right here’s a modified finger relaxation for the ROG Spatha gaming mouse:

The ROG Spatha fitted with a 3D-printed finger relaxation

…and with the unique finger relaxation

Clearly, these 3D-printed components can’t compete with the standard that devoted manufacturing processes present. However when choices are restricted or customization is desired, they provide savvy DIYers a possibility to experiment and discover a workable answer.

FreeCAD and 3D supply recordsdata

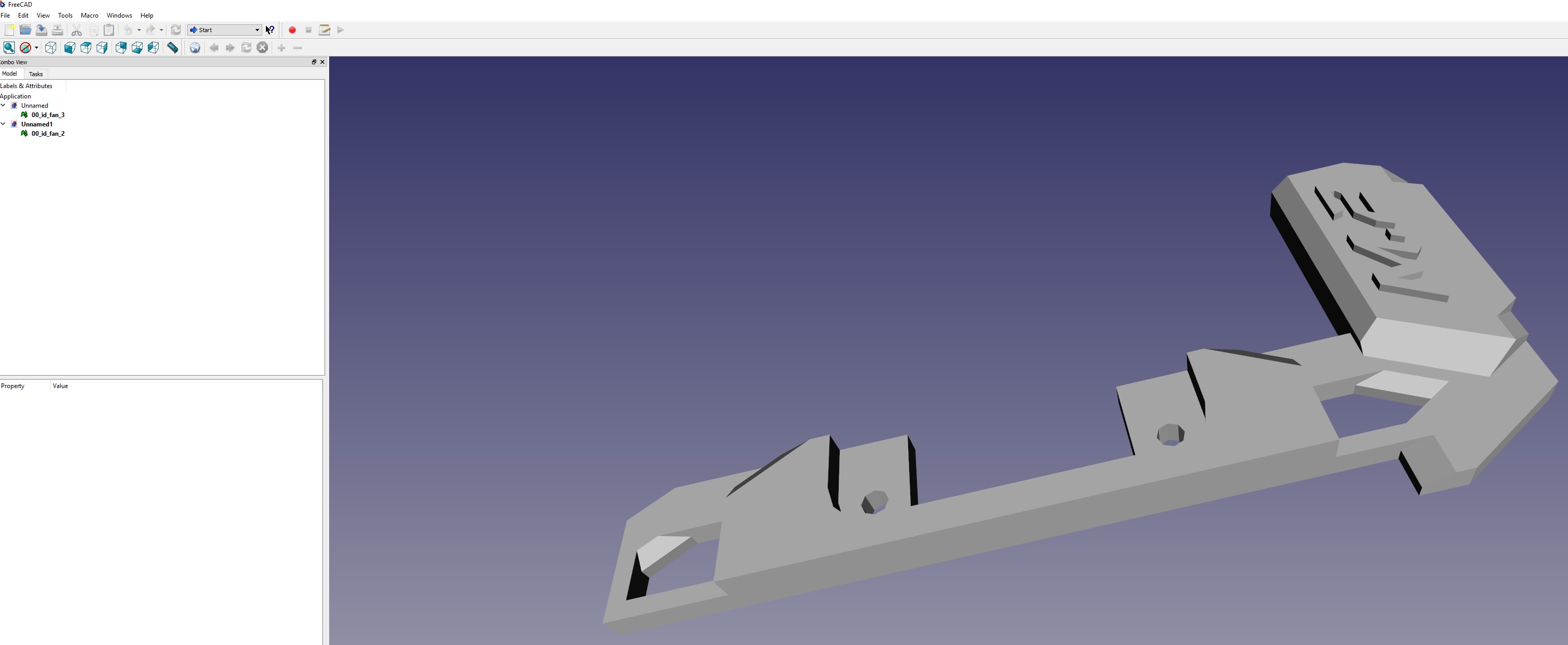

Earlier than we revealed this text, we needed to see how troublesome it will be to control the 3D recordsdata for these components ourselves. We discovered a program referred to as FreeCAD that, because the title implies, is totally free to make use of. I can’t fake to understand how versatile this software program is from a design perspective, nevertheless it’s completely able to importing, manipulating, and exporting recordsdata within the codecs utilized by distributors who promote 3D-printed components and makers who print their very own items.

A 3D supply file in FreeCAD

The FreeCAD studying curve is steep, however investing a while ought to permit you modify current components, add textual content, or change different attributes.

When you’d prefer to print any of the gadgets we’ve mentioned your self–or take a stab at modifying them–head over to the ROG boards to obtain the supply recordsdata. For customers based mostly in North America or Europe who don’t have entry to a 3D printer, we suggest utilizing an internet printing service like Shapeways, which has a large alternative of supplies and colours. They’ve obtained places of work within the US and the EU that supply affordable regional transport charges.